Base Preparation for Walkways/Driveways

For decades, experts in the industry have recommended a particular technique in how contractors and homeowners should install interlocking pavers, particularly the base preparation.

We will shed some light on this technique, and then discuss a somewhat new method that has been gaining a lot of traction over the last few years.

Non-open Graded Base

The most common technique is non-open graded base. What this means is that the compacted granular base portion of the job is using a 3⁄4” Crusher Run Gravel (also called Granular “A”).

This is a combination of angular 3⁄4” stone mixed with fines and when compacted this material creates a solid base for the next step; the bedding course. Typically the bedding course is only 1” thick and is made up of a mason or concrete sand to achieve a final, smooth layer to install the paving stones on.

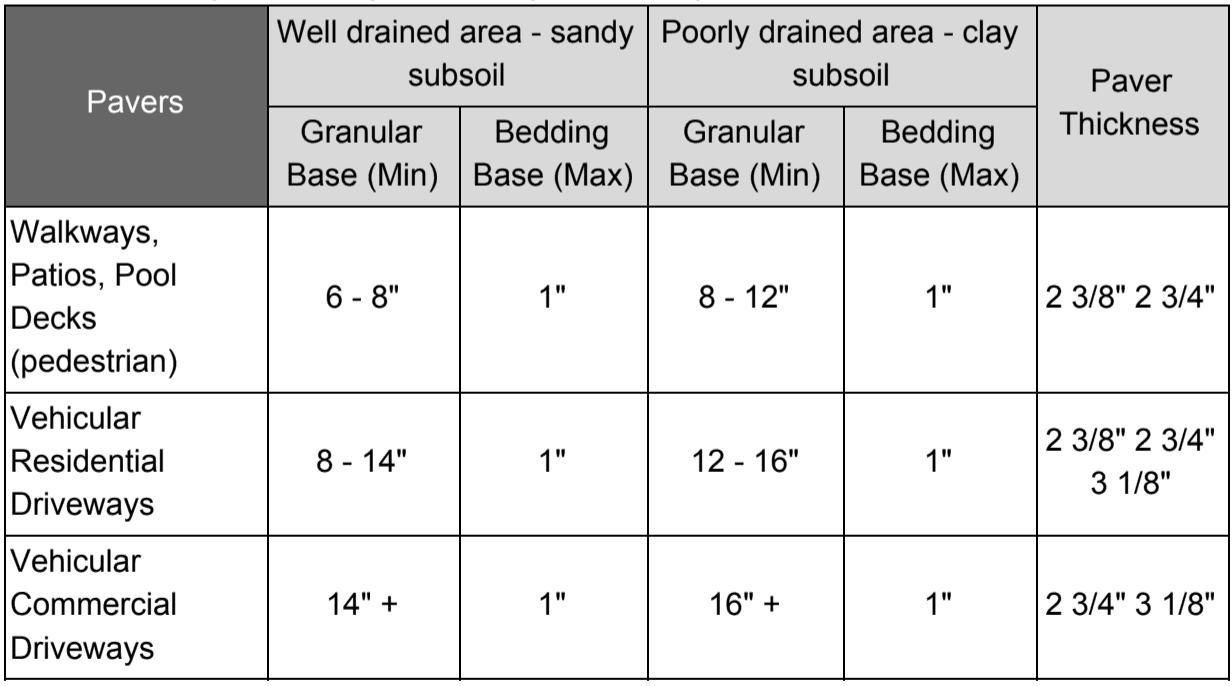

It is important to note that how much you excavate for your project largely depends on the kind of traffic it will see. Is it foot traffic, or will there be vehicles driving and parking? Is the soil sandy or clay dominant?

Use the following chart as a guideline for your next project.

Please note: It used to be acceptable to install “screenings” (a finely crushed limestone product) as your bedding course. This is no longer an accepted bedding course material. While it has a great compaction rate, it leaves little to no room for drainage, causing issues during freeze/thaw cycles.

Open Graded Base

Open graded base has been around for a few years now, and is quickly gaining ground on the new standard of base preparation.

This is a permeable base system which uses 3⁄4” Clear gravel and a course stone bedding layer as opposed to sand. The bedding layer is often referred to as 1⁄8” Chip or HPB (high performance bedding).

This method allows for proper drainage and the load-bearing capacity necessary for appropriate traffic.

This method has a number of benefits such as:

- Easier products to work with. The clear stone material means the product can be used during rainy days and compacted all the same. You can walk on the material without disturbing your levels. Still requires compaction, but less of it.

- Proper drainage means the base will not be affected by the freeze/thaw cycle.

- Insects and weed roots have a difficult time thriving in a base that has no fine materials.

- Can be used for all product sizes.

Excavation / Depths

Excavation and depths required for your project are the same no matter the method you choose to use. The difference here is the product used for your base material. Some research has stated that less excavation is required for an Open Graded Base, but most contractors continue to stick to the standard excavation depths.

One final major point for open graded base is that once you have excavated for your project, you must install a landscape fabric that is permeable. This will prevent the sub-soil from coming in contact with the clear stone, all while allowing water to pass through.

If soil is allowed to leach into the clear stone, it will defeat the purpose of open graded base.

Conclusion

It is our job as suppliers to help educate both homeowners and contractors (although sometimes they also educate us). These two methods are both accepted in the industry.

The important thing to note is that there is a lot of research going in to construction practices and our industry leaders (contractors and suppliers) are continuing to ensure that the way we build for our clients is the right way!

There is more to installing walkways, driveways or walls than what is listed here. If you have anymore questions please contact us at 519-426-2246.